Flat Sheets

Flat Sheets – Universally Applicable for Flashings, Repairs & Custom Solutions

Our flat sheets are the ideal foundation for individual flashings, repair work, and tailor-made metal solutions for roofs and facades.

They consist of high-quality steel or aluminum sheet, are factory-filmed, and can be easily cut, folded, or shaped – entirely according to your needs.

Whether for cutting eave flashings, covers, corner profiles, or individual custom parts – with our flat sheets, you are flexible in processing and color design.

Showing the single result

Product Details

Dimensions:

Standard size: 2.00 m x 1.25 m

Other lengths or custom cuts are available individually upon request.

Material Thicknesses:

-

Steel sheet in 0.50 mm, 0.63 mm, or 0.75 mm

-

Aluminum sheet in 0.70 mm

Protective Film:

Every flat sheet is provided with a protective film to protect the surface during transport and folding.

Transport:

For orders of 10 sheets or more, delivery is made on a sturdy wooden pallet (flat rate transport cost of €30).

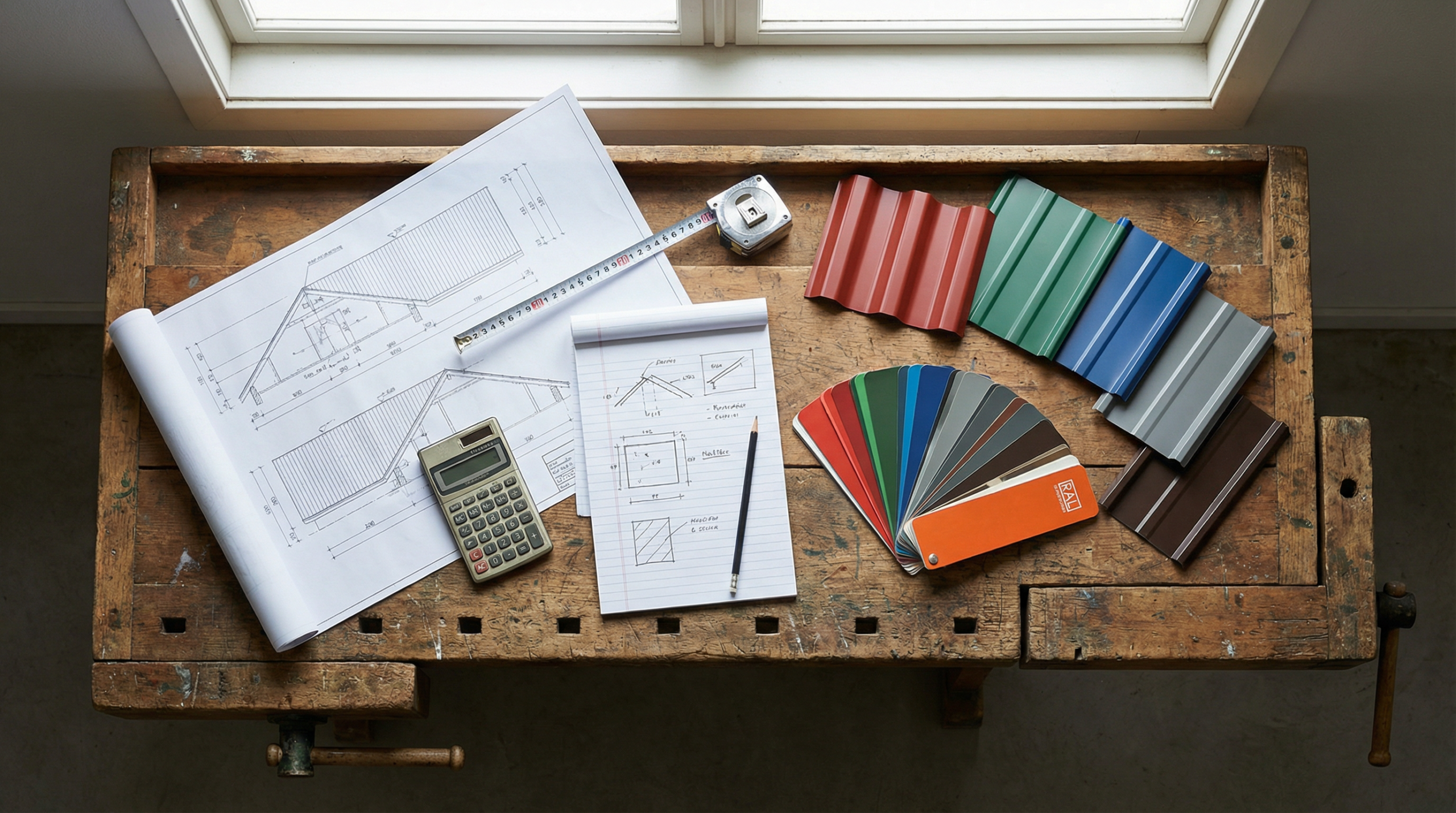

Materials and Coatings

Our flat sheets are available in the same durable coatings as our roof and wall systems – for perfect visual and technical compatibility:

-

Aluzinc (AZ 150)

-

Standard Polyester (25 µm)

-

Matt Coarse-Grain Polyester (35 µm)

-

PURLAK® (50 µm)

-

PURMAT® (50 µm)

Color Options

Flat sheets are available in many RAL colors – matched to the entire range of roofing sheets, wall panels, and flashings. Examples include: RAL 7016 (Anthracite Grey), RAL 8017 (Chocolate Brown), RAL 9006 (White Aluminum), and RAL 8012 (Red Brown).

Applications

-

Production of individual flashings (eave plates, barge boards, wall connections)

-

Repairs and retrofitting of roof and facade systems

-

Covers, trims, and protective cladding

-

Custom fabrications (available on request up to 6 m length)

Advantages of Our Flat Sheets

-

Matches all Polmetal roof and wall profiles

-

Durable coatings and surfaces

-

Protective film for processing-friendly handling

-

Ideal for folding, cutting, and machining

-

Available in many RAL colors and thicknesses

Processing Instructions

Our flat sheets can be processed without problems using conventional folding machines, guillotine shears, or tin snips. During folding, the film layer should remain on the outside to avoid scratches on the visible side. After assembly, the protective film can simply be peeled off.

Summary

With our flat sheets, you are perfectly equipped for every detail – from individual flashings to small repairs and professional custom solutions. Durable, dimensionally stable, and color-coordinated – the perfect addition to our roof and wall systems.